Softening paste has revolutionized textile manufacturing. It enhances fabric softness, improves texture, and elevates product quality. You can now meet consumer demands for premium textiles while supporting sustainability. Jindun Chemical’s advanced softening solutions provide unmatched performance, helping you achieve superior results and set new benchmarks in the industry.

Benefits of Softening Paste in Textile Manufacturing

Enhancing Fabric Quality and Softness

Softening paste plays a vital role in improving the texture and feel of textiles. It transforms rough fabrics into smooth, luxurious materials that appeal to consumers. By applying softening paste during production, you can achieve a consistent softness across various fabric types. This ensures that your products meet the high standards expected in today’s competitive market.

Softening paste doesn’t just enhance the tactile experience; it also improves the overall appearance of textiles. Fabrics treated with it look more refined and premium, making them ideal for high-end applications.

Improving Durability and Longevity of Textiles

Textiles treated with softening paste last longer and perform better over time. The paste strengthens fibers, reducing wear and tear during use. This added durability makes your products more reliable, which is essential for building trust with your customers.

Softening paste also protects fabrics from damage during washing and drying. It minimizes shrinkage and helps maintain the original shape of garments. This ensures that your textiles retain their quality even after repeated use.

Boosting Consumer Satisfaction with Premium-Quality Products

When you use softening paste, you create textiles that stand out in the market. Consumers value fabrics that feel soft, look elegant, and last longer. By delivering these qualities, you can enhance customer satisfaction and loyalty.

Offering premium-quality products not only meets consumer expectations but also elevates your brand’s reputation. Softening paste helps you achieve this by adding value to every textile you produce.

Applications of Softening Paste in Textile Production

Role in Pre-Treatment and Finishing Processes

Softening paste plays a critical role in both pre-treatment and finishing stages of textile production. During pre-treatment, it prepares fabrics by reducing stiffness and improving flexibility. This ensures that the material is easier to handle during subsequent processes like dyeing or printing. In the finishing stage, softening paste enhances the final texture and feel of the fabric. It creates a smooth, luxurious surface that appeals to consumers.

You can also use softening paste to improve the drape and flow of textiles. This makes it ideal for garments, upholstery, and other applications where fabric movement matters. By incorporating it into your production workflow, you ensure consistent quality from start to finish.

Compatibility with Various Fabric Types and Textures

Softening paste works effectively with a wide range of fabric types. Whether you are processing natural fibers like cotton and silk or synthetic materials like polyester and nylon, it delivers excellent results. Its versatility allows you to achieve the desired softness and texture for each fabric type.

You can also use it to enhance the performance of blended fabrics. For example, it improves the elasticity of knitted materials and the smoothness of woven textiles. This adaptability makes softening paste a valuable tool for manufacturers working with diverse materials.

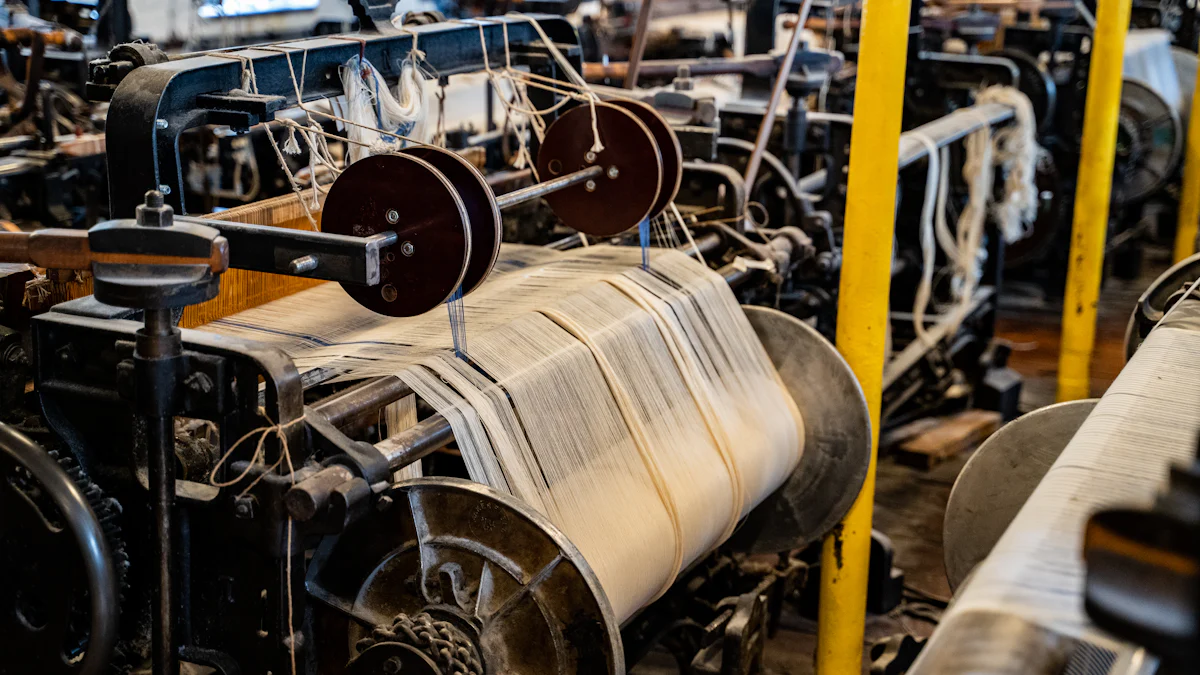

Integration with Modern Textile Technologies

Modern textile technologies demand solutions that are both efficient and adaptable. Softening paste integrates seamlessly with advanced machinery and automated systems. This ensures that you can achieve consistent results without disrupting your production line.

You can also combine it with other textile auxiliary agents to enhance its effectiveness. For instance, pairing it with anti-static agents or moisture controllers can further improve fabric performance. This flexibility allows you to meet specific production goals while maintaining high standards of quality.

Addressing Future Challenges with Softening Paste

Supporting Sustainability Goals in Textile Manufacturing

You can use softening paste to align your production processes with sustainability goals. It reduces the need for harsh chemicals, which minimizes environmental impact. By incorporating it into your workflow, you lower water and energy consumption during textile finishing. This helps you meet global standards for eco-friendly manufacturing.

Softening paste also enhances the durability of fabrics, reducing waste caused by frequent replacements. Longer-lasting textiles mean fewer resources are needed for production. This makes your operations more sustainable while appealing to environmentally conscious consumers.

Sustainability is no longer optional. It is a necessity for staying relevant in the textile industry. Softening paste offers a practical solution to achieve this.

Meeting Evolving Consumer Expectations for Eco-Friendly and High-Quality Products

Today’s consumers demand products that are both high-quality and eco-friendly. Softening paste helps you meet these expectations by improving fabric softness and texture without compromising sustainability. It allows you to create textiles that feel luxurious while adhering to green practices.

You can also use softening paste to enhance the performance of natural and synthetic fabrics. This versatility ensures that your products cater to diverse consumer preferences. By delivering premium textiles with a reduced environmental footprint, you build trust and loyalty among your customers.

Enhancing Industry Competitiveness Through Innovation

Innovation drives success in the textile industry. Softening paste integrates seamlessly with modern technologies, enabling you to stay ahead of competitors. Its compatibility with advanced machinery ensures efficient production without sacrificing quality.

You can combine softening paste with other textile auxiliary agents to create unique fabric properties. For example, pairing it with anti-static agents improves fabric performance in specialized applications. This adaptability allows you to innovate and offer products that stand out in the market.

By embracing softening paste, you position your business as a leader in quality and sustainability. This strengthens your competitive edge in 2025 and beyond.

Softening paste is transforming textile manufacturing. You can rely on Jindun Chemical’s advanced solutions to enhance fabric quality and meet sustainability goals.

- Key Benefits:

- Improves softness and durability.

- Supports eco-friendly production.

Softening paste is indispensable for staying competitive in 2025. It empowers you to create premium textiles while addressing industry challenges.

Post time: Jan-13-2025