When it comes to cable insulation, LDPE stands out as a remarkable solution. You benefit from its flexibility, which allows cables to bend without breaking. This material also offers excellent moisture resistance, ensuring that your cables remain safe and functional in damp environments. Additionally, LDPE provides superior electrical insulation capabilities, protecting your cables from electrical faults. These features make LDPE an ideal choice for various applications, ensuring reliability and performance.

Key Takeaways

- LDPE offers exceptional flexibility, allowing cables to bend without breaking, making it ideal for applications with frequent movement.

- Its excellent moisture resistance protects cables from water damage, ensuring reliable performance in damp environments.

- LDPE provides superior electrical insulation capabilities, minimizing energy loss and preventing dangerous electrical faults.

- The cost-effectiveness of LDPE makes it an attractive choice for large-scale projects, delivering high-quality insulation without exceeding budgets.

- LDPE’s ease of processing simplifies manufacturing, allowing for efficient production and adaptability to various cable designs.

- Choosing LDPE enhances the long-term reliability of cable systems, reducing maintenance needs and extending the lifespan of cables.

- Industries such as telecommunications and power transmission significantly benefit from LDPE’s properties, ensuring performance and safety in challenging environments.

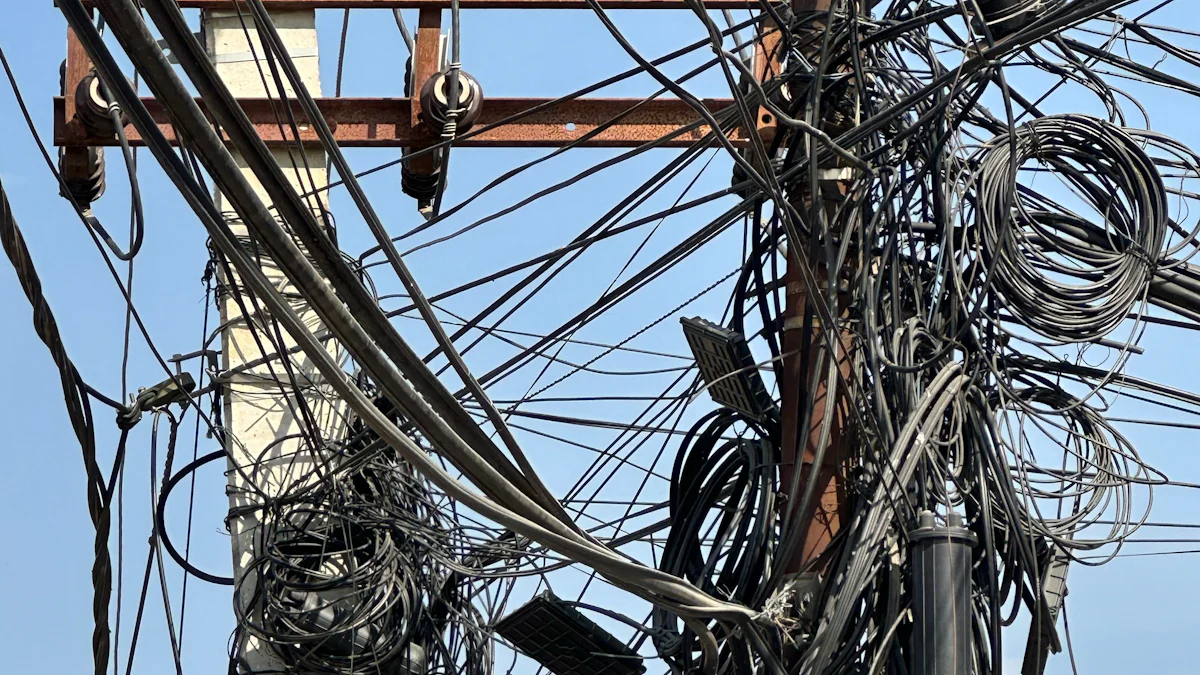

Understanding Cable Insulation Challenges

When you think about cable insulation, several challenges come to mind. These challenges can affect the performance and longevity of cables. Let’s explore some of these issues.

Environmental Stress

Cables often face harsh environmental conditions. You might encounter extreme temperatures, UV radiation, or moisture. These factors can degrade cable materials over time. For instance, exposure to sunlight can cause materials to become brittle. Moisture can lead to corrosion or short circuits. Choosing the right insulation material helps you combat these environmental stresses effectively.

Mechanical Wear

Cables undergo constant movement and bending. This mechanical wear can lead to cracks or breaks in the insulation. You need a material that can withstand repeated flexing without losing integrity. LDPE offers excellent flexibility, making it a suitable choice for applications where cables experience frequent movement.

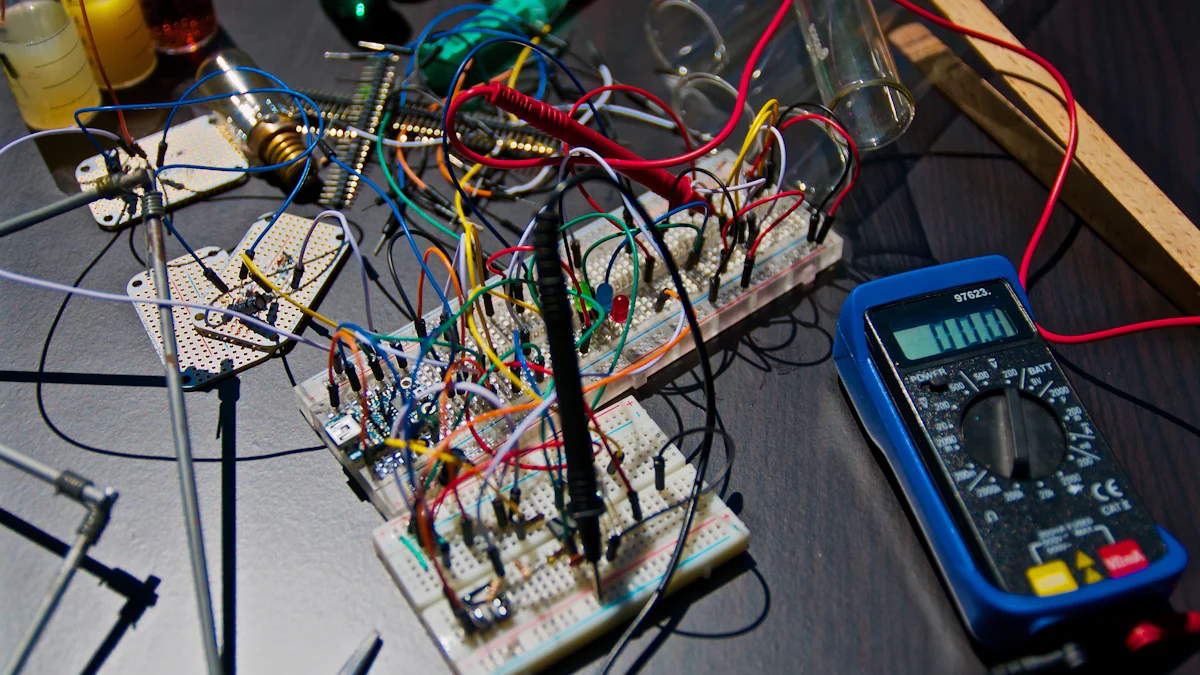

Electrical Performance

Electrical performance is crucial for cable insulation. You want to ensure that the insulation prevents electrical faults. Poor insulation can lead to energy loss or dangerous short circuits. LDPE provides superior electrical insulation capabilities, ensuring that your cables perform reliably. This makes it an ideal material for maintaining electrical safety and efficiency.

Properties of LDPE

Flexibility and Durability

You will find that LDPE offers remarkable flexibility, which is essential for cable insulation. This flexibility allows cables to bend and twist without breaking. You can rely on LDPE to maintain its integrity even under constant movement. Its durability ensures that the insulation remains intact over time, reducing the risk of cracks or breaks. This makes LDPE a preferred choice for applications where cables experience frequent bending and flexing.

Moisture and Chemical Resistance

LDPE provides excellent resistance to moisture and chemicals. You can trust it to protect cables from water damage, which is crucial in damp environments. This resistance prevents moisture from penetrating the insulation, reducing the risk of corrosion or electrical faults. Additionally, LDPE withstands exposure to various chemicals, ensuring that the insulation remains effective in harsh conditions. This property makes LDPE suitable for use in industrial settings where chemical exposure is common.

Electrical Insulation Capabilities

When it comes to electrical insulation, LDPE excels. You can count on it to provide superior insulation capabilities, preventing electrical faults and ensuring safety. LDPE minimizes energy loss, making it an efficient choice for cable insulation. Its ability to maintain electrical performance over time ensures that your cables operate reliably. This makes LDPE an ideal material for applications where electrical safety and efficiency are paramount.

Advantages of Using LDPE in Cable Insulation

Cost-Effectiveness

You will find that LDPE offers a cost-effective solution for cable insulation. Its production process is efficient, which helps keep costs low. This affordability makes it an attractive choice for large-scale projects. You can achieve high-quality insulation without exceeding your budget. By choosing LDPE, you ensure that your investment in cable insulation remains economical while maintaining excellent performance.

Ease of Processing

LDPE stands out for its ease of processing. You can easily mold and shape it to fit various cable designs. This adaptability simplifies the manufacturing process, reducing production time. You benefit from its compatibility with standard extrusion equipment, which streamlines operations. The straightforward processing of LDPE allows you to produce cables efficiently, meeting the demands of different applications with minimal hassle.

Long-Term Reliability

When you choose LDPE for cable insulation, you gain long-term reliability. Its durability ensures that cables remain functional over extended periods. You can trust LDPE to withstand environmental stresses and mechanical wear. This reliability reduces maintenance needs and extends the lifespan of your cables. By opting for LDPE, you secure a dependable insulation material that supports the longevity and performance of your cable systems.

Case Studies/Examples

Telecommunications Industry

In the telecommunications industry, you often encounter the need for reliable cable insulation. LDPE has proven to be a game-changer here. Its flexibility and durability make it ideal for use in fiber optic cables. You can trust LDPE to maintain signal integrity over long distances. This material resists environmental stress, ensuring that your communication lines remain clear and uninterrupted.

Consider a scenario where you need to lay cables in a coastal area. The salty air and moisture can wreak havoc on traditional materials. With LDPE, you gain peace of mind. Its moisture resistance protects the cables from corrosion. You ensure that your network operates smoothly, even in challenging environments. This reliability makes LDPE a preferred choice for telecommunications companies worldwide.

Power Transmission

Power transmission systems demand robust insulation materials. You need cables that can withstand high voltages and harsh conditions. LDPE rises to the occasion with its superior electrical insulation capabilities. It minimizes energy loss, ensuring efficient power delivery across vast distances.

Imagine a power grid spanning a desert region. The extreme temperatures and UV exposure can degrade many materials. LDPE, however, stands strong. Its weather resistance ensures that your cables remain functional, even under intense sun. You benefit from reduced maintenance costs and increased system reliability.

In urban settings, where space is limited, you require cables that can bend and fit into tight spaces. LDPE’s flexibility allows you to design compact and efficient power systems. You can trust it to maintain performance, even in densely packed installations. By choosing LDPE, you enhance the safety and efficiency of your power transmission networks.

You have seen how LDPE effectively addresses cable insulation challenges. Its flexibility, moisture resistance, and electrical insulation capabilities make it a preferred material. You benefit from its cost-effectiveness and ease of processing. LDPE ensures long-term reliability in various applications, from telecommunications to power transmission. By choosing LDPE, you enhance the performance and durability of your cable systems. This material stands out as a reliable solution for modern insulation needs.

FAQ

What is LDPE, and why is it used in cable insulation?

LDPE stands for Low-Density Polyethylene. You use it in cable insulation because of its flexibility, moisture resistance, and excellent electrical insulation properties. These features make LDPE a reliable choice for protecting cables in various environments.

How does LDPE compare to other insulation materials?

You will find that LDPE offers superior flexibility and moisture resistance compared to many other materials. It provides excellent electrical insulation, ensuring safety and efficiency. Its cost-effectiveness and ease of processing also make it a preferred choice for many applications.

Can LDPE withstand harsh environmental conditions?

Yes, LDPE can withstand harsh conditions. You benefit from its resistance to UV radiation, extreme temperatures, and moisture. This makes it suitable for outdoor and industrial applications where environmental stress is a concern.

Is LDPE suitable for high-voltage applications?

LDPE is suitable for high-voltage applications. You can rely on its superior electrical insulation capabilities to minimize energy loss and ensure efficient power delivery. This makes it an ideal choice for power transmission systems.

How does LDPE contribute to the longevity of cables?

LDPE contributes to cable longevity by providing durable insulation that resists environmental stress and mechanical wear. You will notice reduced maintenance needs and extended cable lifespan when using LDPE, ensuring long-term reliability.

What industries benefit most from using LDPE in cable insulation?

Industries such as telecommunications and power transmission benefit significantly from using LDPE. You will find that its flexibility, durability, and electrical insulation properties make it ideal for these sectors, enhancing performance and reliability.

How does LDPE handle chemical exposure?

LDPE handles chemical exposure well. You can trust it to resist various chemicals, maintaining effective insulation even in harsh industrial settings. This makes it a versatile choice for environments where chemical exposure is common.

Is LDPE environmentally friendly?

LDPE is considered environmentally friendly. You benefit from its recyclability, which reduces waste and supports sustainable practices. Its production process also minimizes environmental impact, making it a responsible choice for cable insulation.

Can LDPE be used in both indoor and outdoor applications?

Yes, you can use LDPE in both indoor and outdoor applications. Its resistance to environmental stress and mechanical wear makes it suitable for a wide range of settings, ensuring reliable performance regardless of location.

How does LDPE improve cable manufacturing processes?

LDPE improves manufacturing processes with its ease of processing. You can easily mold and shape it to fit various cable designs, streamlining production. Its compatibility with standard extrusion equipment further simplifies operations, allowing efficient cable production.

Post time: Dec-19-2024