You can now achieve superior textile quality with innovative solutions like SPECIAL PRINTING ADDITIVE & OTHERS. These advanced additives enhance durability, improve color vibrancy, and refine texture. They address the growing need for high-performance fabrics while meeting sustainability goals. By using these cutting-edge products, you ensure textiles that stand out in both functionality and aesthetics.

What Are SPECIAL PRINTING ADDITIVE & OTHERS and Their Role in Textiles?

Definition and Overview of Special Printing Additives

Special printing additives are advanced chemical solutions designed to improve the quality and functionality of textiles during the printing and finishing processes. These additives enhance fabric properties such as durability, color precision, and texture. They also optimize production efficiency by addressing common challenges like uneven dyeing or static buildup. You can think of them as essential tools that help manufacturers create textiles that meet modern demands for performance and aesthetics. In 2025, these additives have become indispensable for producing high-quality fabrics that stand out in competitive markets.

Key Features of Jindun Chemical’s Textile Auxiliary Agent

Jindun Chemical’s Textile Auxiliary Agent offers a comprehensive range of solutions tailored to the textile industry. Its anti-static agents eliminate static electricity, ensuring smooth production. The stiffening agents provide structure and durability, making fabrics ideal for applications requiring rigidity. Moisture controllers enhance comfort by managing water retention in polyester blends. Flame-retardant agents improve safety by reducing ignition risks. Softening agents, including silicone softeners, deliver luxurious textures and wrinkle resistance. These features make Jindun Chemical’s additives versatile and effective for both natural and synthetic fibers.

How These Additives Address Challenges in Textile Manufacturing

Textile manufacturing often faces issues like uneven dye absorption, static interference, and poor fabric texture. SPECIAL PRINTING ADDITIVE & OTHERS solve these problems by improving dye penetration, reducing static, and enhancing fabric softness. For example, anti-static agents prevent disruptions during fiber processing, while softening agents ensure a premium feel. By integrating these additives, you can achieve consistent quality and meet customer expectations for superior textiles.

Technologies and Methods for Applying SPECIAL PRINTING ADDITIVE & OTHERS

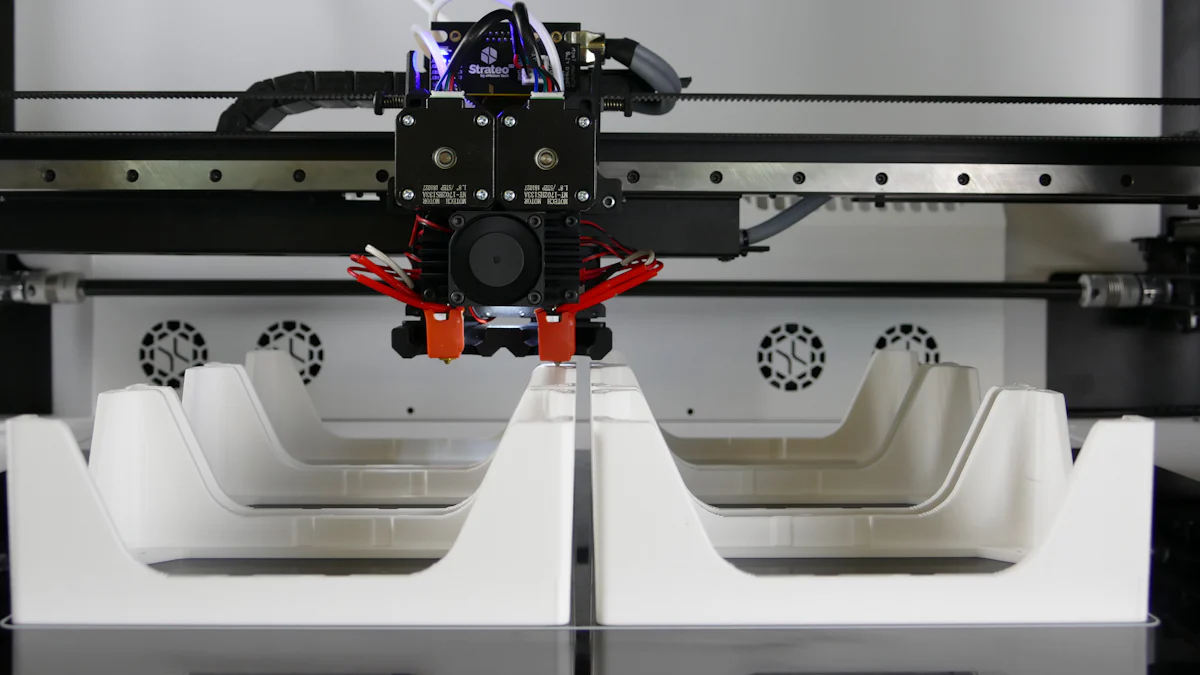

Advanced Printing Techniques (e.g., Digital Printing, Screen Printing)

You can achieve remarkable results by pairing SPECIAL PRINTING ADDITIVE & OTHERS with advanced printing techniques. Digital printing, for instance, allows you to apply intricate designs with precision. This method works well with additives that enhance color vibrancy and ensure even dye distribution. Screen printing, on the other hand, is ideal for bold patterns and high-volume production. Additives improve ink adhesion and prevent smudging, giving you consistent quality. Both techniques benefit from additives that optimize fabric texture and durability, ensuring your textiles meet modern standards.

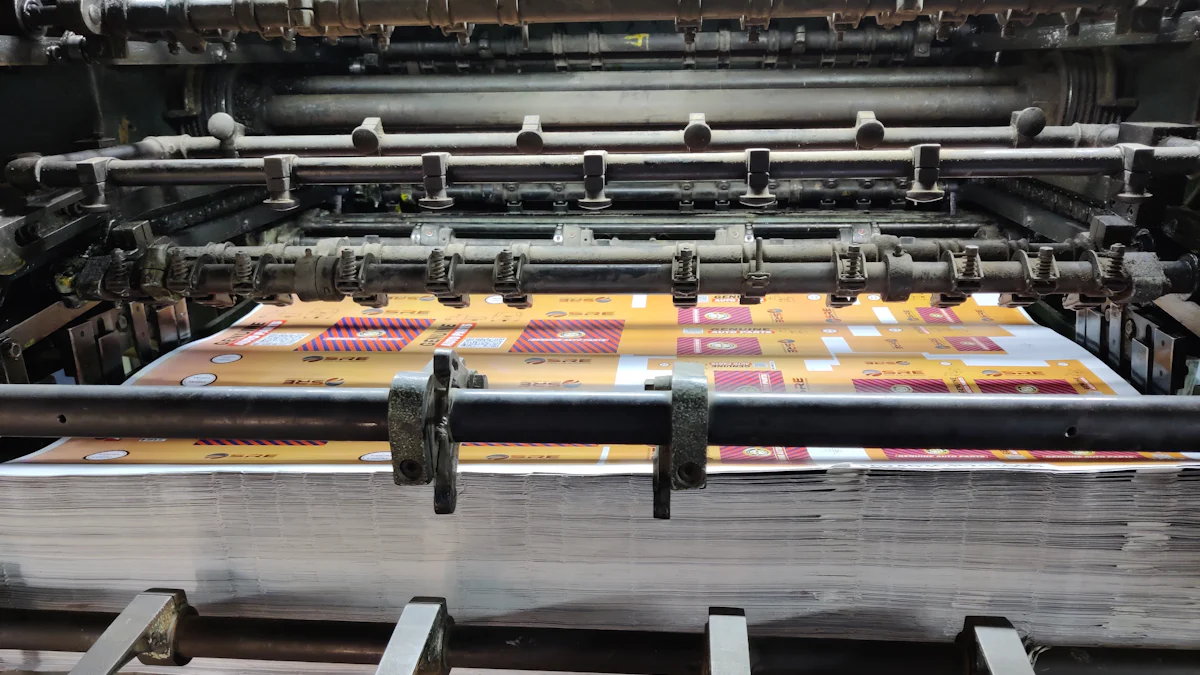

Integration of Additives in Textile Production Processes

Incorporating SPECIAL PRINTING ADDITIVE & OTHERS into your production process is straightforward. During pre-treatment, you can use anti-static agents to eliminate static buildup, ensuring smooth fiber handling. In the dyeing stage, additives improve dye absorption and prevent uneven coloring. Post-treatment steps, such as finishing, benefit from softening agents that enhance the fabric’s feel and appearance. By integrating these additives at key stages, you streamline production and achieve superior results. This approach ensures your textiles stand out in both quality and functionality.

Innovations in Additive Formulations for Enhanced Performance

Recent innovations in additive formulations have transformed textile manufacturing. You now have access to additives designed for specific fibers, such as polyester or cotton blends. Silicone-based softeners, for example, provide unmatched softness and elasticity. Flame-retardant agents meet safety standards without compromising fabric quality. Moisture controllers enhance comfort by regulating water retention. These advancements allow you to tailor your textiles to meet diverse customer needs. With SPECIAL PRINTING ADDITIVE & OTHERS, you can stay ahead in a competitive market by delivering cutting-edge solutions.

Benefits of SPECIAL PRINTING ADDITIVE & OTHERS for Textile Quality

Improved Durability and Longevity of Fabrics

You want fabrics that last longer and maintain their quality over time. SPECIAL PRINTING ADDITIVE & OTHERS enhance the durability of textiles by strengthening fibers during the production process. For example, stiffening agents improve the structural integrity of fabrics, making them resistant to wear and tear. Anti-flammable agents also contribute to longevity by reducing the risk of damage caused by fire. These additives ensure that your textiles can withstand repeated use and maintain their original appearance, even after multiple washes. By using these solutions, you create products that meet customer expectations for reliability and value.

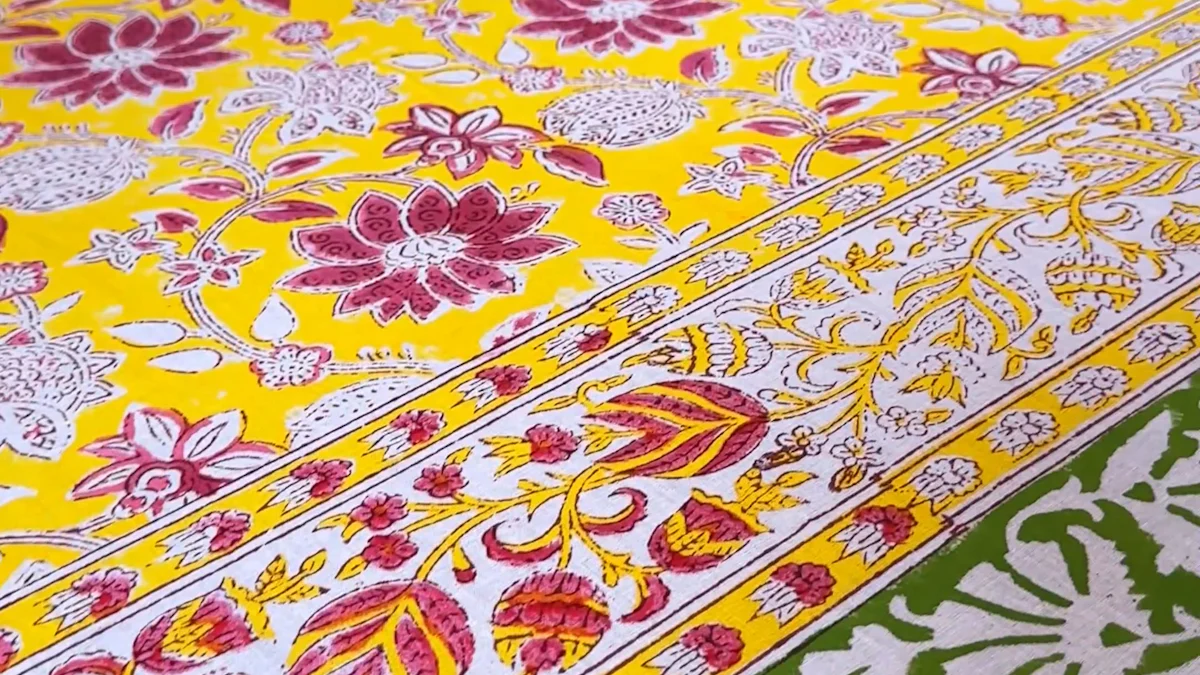

Enhanced Color Vibrancy and Precision

Achieving vibrant and precise colors is essential in textile production. SPECIAL PRINTING ADDITIVE & OTHERS optimize dye absorption, ensuring that colors appear rich and consistent across the fabric. Additives like moisture controllers help regulate the dyeing process, preventing uneven coloring or fading. This results in textiles with sharp, eye-catching designs that stand out in any setting. Whether you’re producing high-end fashion or performance fabrics, these additives help you deliver products with superior color quality. Customers will notice the difference in the vibrancy and clarity of your textiles.

Texture and Feel Improvements for Premium Appeal

The way a fabric feels can make or break its appeal. Softening agents, such as silicone softeners, give textiles a luxurious texture that customers love. These additives enhance softness while maintaining elasticity and durability. Fuzzing agents add a plump, smooth feel, making fabrics more comfortable to wear. By incorporating these solutions, you can create textiles that not only look premium but also feel exceptional. This attention to texture ensures your products stand out in competitive markets, attracting customers who value quality and comfort.

Real-World Applications and Case Studies

Use in High-End Fashion and Luxury Textiles

You can see the impact of SPECIAL PRINTING ADDITIVE & OTHERS in high-end fashion. Designers rely on these additives to create fabrics with vibrant colors and luxurious textures. Softening agents, like silicone softeners, give garments a smooth and premium feel. Anti-static agents ensure flawless production, especially for delicate materials like silk or satin. These additives also help achieve intricate patterns and precise designs, making them essential for luxury brands. By using these solutions, you can produce textiles that meet the highest standards of elegance and quality.

Applications in Sportswear and Performance Fabrics

Sportswear manufacturers use these additives to enhance fabric performance. Moisture controllers improve comfort by managing sweat and keeping fabrics dry. Flame-retardant agents add safety features, especially for outdoor or extreme sports gear. Stiffening agents provide structure, ensuring durability during intense activities. Additives also improve elasticity, making fabrics more flexible and suitable for activewear. With these solutions, you can create sportswear that combines functionality and style, meeting the needs of athletes and fitness enthusiasts.

Examples from Sustainable and Eco-Friendly Textile Brands

Sustainable brands use these additives to create eco-friendly textiles. Moisture controllers and softening agents enhance the quality of recycled fibers, making them comparable to new materials. Flame-retardant agents ensure safety without harmful chemicals, aligning with green production goals. Additives also reduce waste by improving production efficiency and fabric longevity. By adopting these solutions, you can support sustainability while delivering high-quality products. These innovations help eco-conscious brands stand out in the competitive textile market.

Future Trends and Innovations in SPECIAL PRINTING ADDITIVE & OTHERS

Smart Textiles and Functional Additives

Smart textiles are transforming the way fabrics interact with the world. You can now create textiles that respond to environmental changes, such as temperature or moisture. Functional additives play a key role in this innovation. For example, moisture controllers enhance the performance of fabrics by regulating water absorption. Anti-static agents improve the conductivity of smart fabrics, making them suitable for wearable technology. These advancements allow you to produce textiles that combine functionality with comfort. By integrating SPECIAL PRINTING ADDITIVE & OTHERS, you can stay ahead in this growing market.

Sustainable and Biodegradable Additive Solutions

Sustainability is no longer optional in textile production. You can adopt biodegradable additives to reduce environmental impact. These solutions break down naturally, leaving no harmful residues. Flame-retardant agents now meet safety standards without using toxic chemicals. Softening agents derived from renewable resources provide eco-friendly alternatives to traditional options. By using these sustainable additives, you can align your products with consumer demand for greener solutions. This approach not only benefits the planet but also enhances your brand’s reputation.

Predictions for Industry Growth and Adoption by 2025

The demand for innovative textile additives will continue to rise. By 2025, you can expect widespread adoption of SPECIAL PRINTING ADDITIVE & OTHERS across various industries. High-end fashion brands will rely on these solutions for premium quality. Sportswear manufacturers will use them to enhance performance and durability. Sustainable brands will integrate biodegradable additives to meet eco-conscious goals. The global market for textile additives is projected to grow significantly, driven by advancements in technology and increasing consumer expectations. Staying updated with these trends will help you maintain a competitive edge.

Special printing additives, like Jindun Chemical’s Textile Auxiliary Agent, empower you to create textiles with unmatched quality. These solutions drive innovation by enhancing durability, vibrancy, and texture. They also support sustainability efforts. By adopting these additives, you stay competitive and meet the demands of a rapidly evolving textile industry.

Post time: Jan-10-2025