Foamed polypropylene revolutionizes cable insulation by enhancing thermal resistance and reducing weight. You benefit from its unique properties, making it an ideal choice for various applications. This material offers improved performance, ensuring cables withstand high temperatures while remaining lightweight. Its cellular structure provides excellent insulation, contributing to energy efficiency. By choosing foamed polypropylene, you gain a reliable solution that meets the demands of modern industries, ensuring durability and performance in challenging environments.

Key Takeaways

- Foamed polypropylene enhances cable insulation by providing superior thermal resistance, making it ideal for high-temperature environments.

- Its lightweight and flexible nature simplifies installation and maintenance, reducing labor time and improving operational efficiency.

- Choosing foamed polypropylene contributes to energy efficiency, leading to lower energy consumption and cost savings for your projects.

- The material’s excellent electrical insulation properties ensure signal integrity, making it essential for telecommunications and other industries.

- Foamed polypropylene supports sustainable practices through eco-friendly manufacturing processes and recyclability, benefiting both the environment and your operations.

- Regular monitoring and inspection of foamed polypropylene insulation are crucial for maintaining performance and extending its lifespan.

- Ensure compatibility with existing systems by consulting with experts and evaluating current infrastructure before installation.

Understanding Foamed Polypropylene

Properties of Foamed Polypropylene

Lightweight and Cellular Structure

Foamed polypropylene stands out due to its lightweight nature. You will find that its cellular structure significantly reduces the material’s density. This feature makes it an excellent choice for applications where weight reduction is crucial. The cellular design not only decreases weight but also enhances the material’s flexibility. This flexibility allows for easier handling and installation, making your work more efficient.

Thermal and Electrical Insulation Capabilities

When it comes to insulation, foamed polypropylene excels. You benefit from its superior thermal resistance, which ensures that cables remain functional even in high-temperature environments. The material’s electrical insulation properties are equally impressive. It provides a reliable barrier against electrical interference, ensuring the integrity of signals transmitted through cables. This dual capability makes foamed polypropylene a preferred choice for various industrial applications.

Manufacturing Process

Extrusion and Expansion Techniques

The production of foamed polypropylene involves advanced extrusion and expansion techniques. You will appreciate how these methods contribute to the material’s unique properties. During extrusion, the polypropylene is heated and forced through a die, creating a continuous shape. The expansion process follows, where a blowing agent introduces gas bubbles into the material. This step forms the cellular structure that defines foamed polypropylene. Mastery of these techniques ensures the production of high-quality insulation material.

Environmental Considerations

In today’s world, environmental sustainability is paramount. You will be pleased to know that the manufacturing process of foamed polypropylene considers ecological impacts. The use of eco-friendly blowing agents minimizes harmful emissions. Additionally, the material’s recyclability contributes to reducing waste. By choosing foamed polypropylene, you support sustainable practices while benefiting from a high-performance insulation solution.

Benefits of Foamed Polypropylene in Cable Insulation

Improved Thermal Resistance

Performance in High-Temperature Environments

You will find that foamed polypropylene excels in high-temperature environments. Its unique structure allows it to maintain integrity and performance even when exposed to extreme heat. This makes it an ideal choice for applications where temperature fluctuations are common. By using foamed polypropylene, you ensure that your cables remain functional and reliable, reducing the risk of failure due to thermal stress.

Energy Efficiency and Cost Savings

Foamed polypropylene contributes significantly to energy efficiency. Its superior insulation properties minimize energy loss, which translates to lower energy consumption. This efficiency not only benefits the environment but also results in cost savings for you. By choosing foamed polypropylene, you invest in a material that reduces operational costs while maintaining high performance.

Reduced Weight and Enhanced Flexibility

Impact on Installation and Maintenance

The lightweight nature of foamed polypropylene simplifies installation and maintenance processes. You will appreciate how easy it is to handle and install, reducing labor time and effort. This ease of use also extends to maintenance, as the material’s flexibility allows for quick adjustments and repairs. By opting for foamed polypropylene, you streamline your operations and enhance overall efficiency.

Transportation and Handling Advantages

Transportation and handling become more manageable with foamed polypropylene. Its reduced weight lowers transportation costs and minimizes the risk of damage during transit. You benefit from easier handling, which reduces the likelihood of accidents and injuries. By incorporating foamed polypropylene into your projects, you improve safety and efficiency in logistics and handling.

Real-World Applications and Case Studies

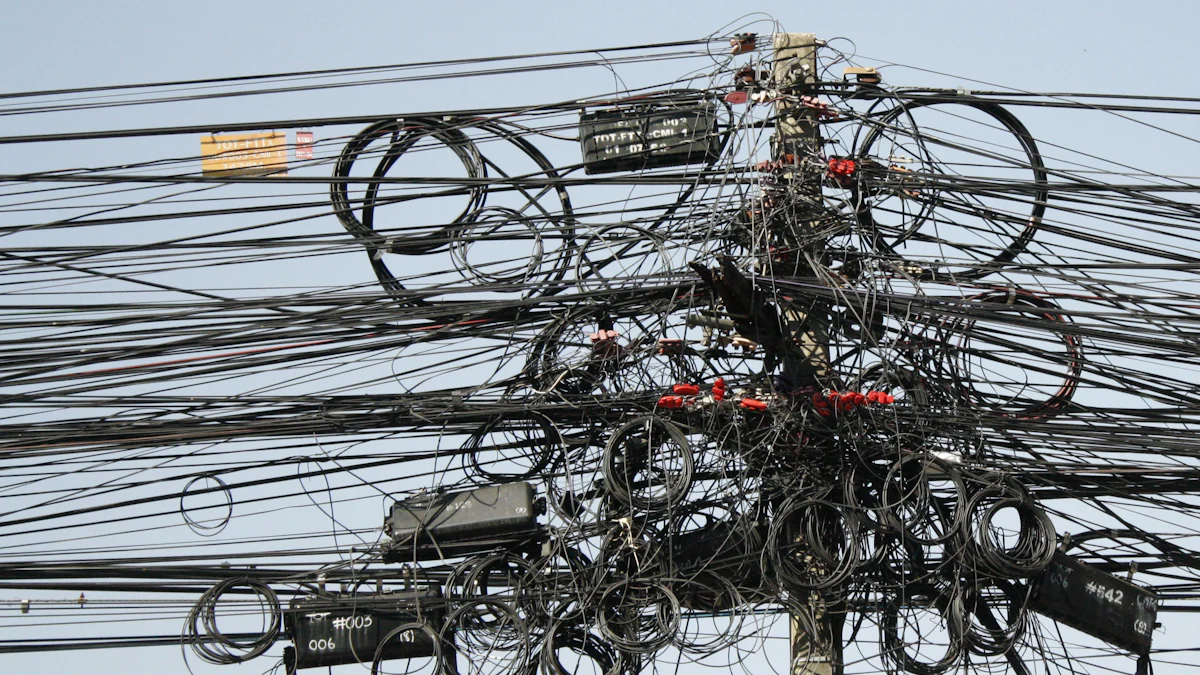

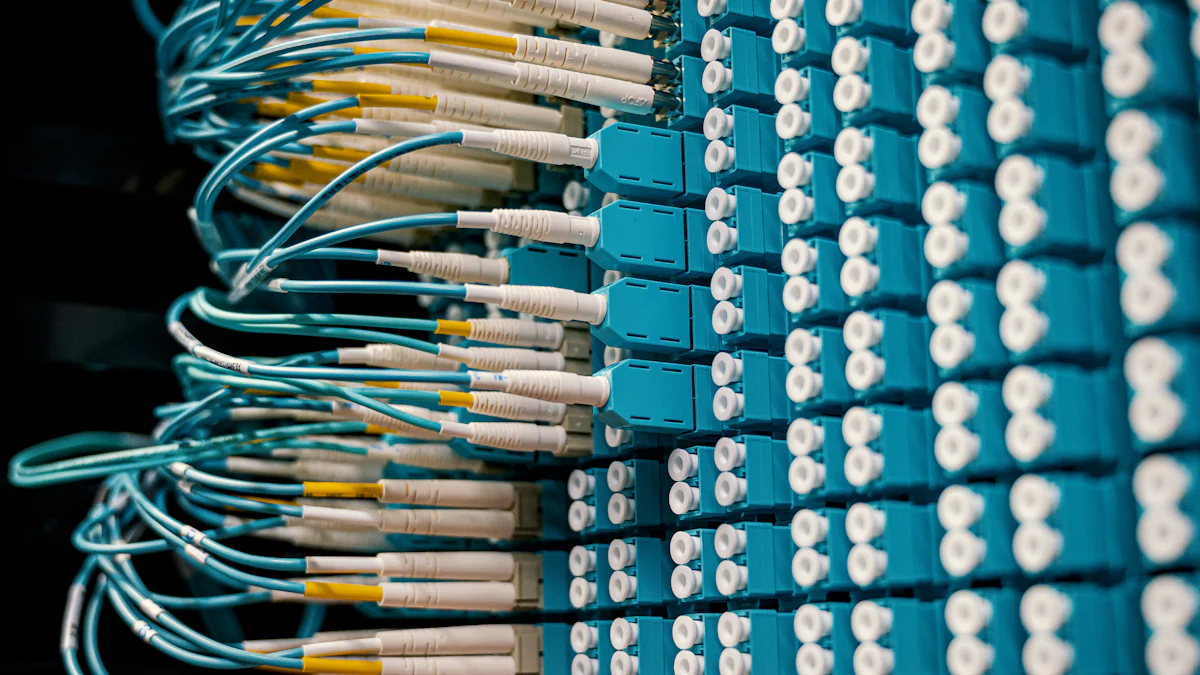

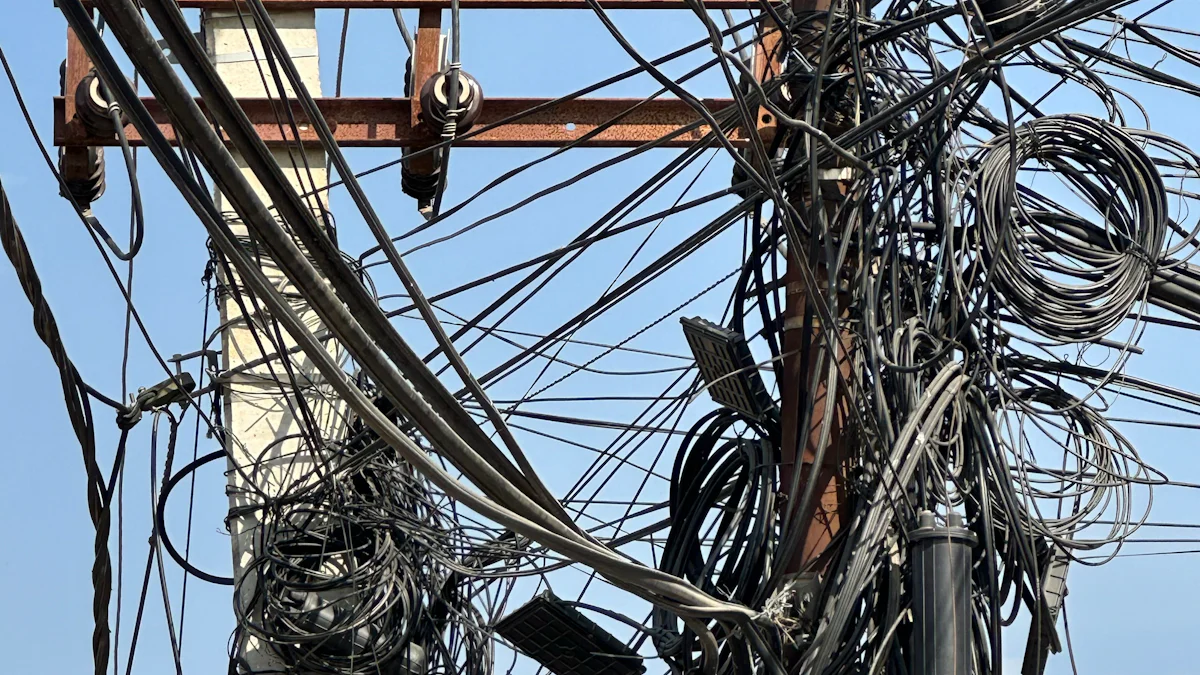

Telecommunications Industry

Enhanced Signal Integrity

In the telecommunications industry, you rely on materials that ensure signal integrity. Foamed polypropylene plays a crucial role here. Its excellent electrical insulation properties prevent interference, maintaining clear and reliable signal transmission. You benefit from reduced signal loss, which enhances the quality of communication. This material’s ability to maintain signal integrity makes it indispensable in modern telecommunication systems.

Longevity and Reliability

You demand longevity and reliability in your telecommunications infrastructure. Foamed polypropylene delivers on both fronts. Its robust structure withstands environmental stressors, ensuring long-term performance. You will find that cables insulated with this material exhibit extended lifespans, reducing the need for frequent replacements. By choosing foamed polypropylene, you invest in a durable solution that supports uninterrupted communication.

Automotive and Aerospace Sectors

Weight Reduction and Fuel Efficiency

In the automotive and aerospace sectors, weight reduction is paramount. Foamed polypropylene offers a lightweight solution that contributes to fuel efficiency. You will notice a significant decrease in vehicle weight, leading to improved fuel economy. This material’s flexibility also aids in design innovation, allowing you to create more efficient and aerodynamic structures. By incorporating foamed polypropylene, you enhance performance while reducing environmental impact.

Case Study: Jindun Chemical’s JD-6127 in High-Temperature Wire Applications

Jindun Chemical’s JD-6127 exemplifies the benefits of foamed polypropylene in high-temperature wire applications. You will appreciate its superior temperature resistance and mechanical strength. This material excels in environments where traditional insulation fails. In a recent project, JD-6127 demonstrated remarkable durability and performance under extreme conditions. By using JD-6127, you ensure reliability and safety in demanding applications, setting a new standard for high-temperature insulation.

Expert Insights on Implementation and Maintenance

Best Practices for Installation

Compatibility with Existing Systems

When integrating foamed polypropylene into your cable insulation systems, you must ensure compatibility with existing infrastructure. Evaluate the current systems to identify any potential conflicts. This step helps you avoid disruptions during installation. You should also consult with manufacturers or experts to confirm that foamed polypropylene aligns with your system’s specifications. By doing so, you optimize performance and maintain system integrity.

Safety and Compliance Standards

Adhering to safety and compliance standards is crucial in any installation process. You need to familiarize yourself with relevant regulations and guidelines specific to foamed polypropylene. These standards ensure that your installation meets industry requirements and protects against potential hazards. Implementing safety measures not only safeguards your operations but also enhances the reliability of your cable systems. Always prioritize compliance to achieve a successful and secure installation.

Maintenance and Longevity

Monitoring and Inspection Techniques

Regular monitoring and inspection are vital for maintaining the longevity of foamed polypropylene insulation. Develop a routine schedule to assess the condition of your cables. Look for signs of wear or damage that could compromise performance. Utilize advanced inspection tools to detect issues early. By staying proactive, you can address problems before they escalate, ensuring continuous operation and extending the lifespan of your insulation.

Troubleshooting Common Issues

Despite its durability, foamed polypropylene may encounter occasional issues. You should familiarize yourself with common problems and their solutions. For instance, if you notice a decrease in insulation performance, investigate potential causes such as environmental factors or mechanical stress. Implement corrective measures promptly to restore functionality. By understanding troubleshooting techniques, you enhance your ability to maintain efficient and reliable cable systems.

Foamed polypropylene offers numerous benefits in cable insulation, including enhanced thermal resistance, reduced weight, and improved flexibility. You can apply it across various industries, from telecommunications to automotive sectors, ensuring reliable performance. Looking ahead, expect innovations that further optimize its properties, making it even more efficient and sustainable. By adopting foamed polypropylene, you position your operations at the forefront of technological advancement, ensuring superior insulation performance and contributing to a more sustainable future. Embrace this material to enhance your projects and meet modern industry demands.

FAQ

What is foamed polypropylene?

Foamed polypropylene is a lightweight, cellular-structured material used in cable insulation. You benefit from its excellent thermal and electrical insulation properties, making it ideal for various industrial applications.

How does foamed polypropylene improve cable insulation?

Foamed polypropylene enhances cable insulation by providing superior thermal resistance and reducing weight. You gain improved performance in high-temperature environments and enjoy easier handling and installation due to its flexibility.

Why should I choose foamed polypropylene over traditional materials?

You should choose foamed polypropylene for its unique combination of lightweight structure, thermal resistance, and electrical insulation capabilities. It offers energy efficiency, cost savings, and durability, making it a preferred choice for modern industries.

Is foamed polypropylene environmentally friendly?

Yes, foamed polypropylene is environmentally friendly. The manufacturing process uses eco-friendly blowing agents, minimizing harmful emissions. Additionally, the material’s recyclability helps reduce waste, supporting sustainable practices.

Can foamed polypropylene be used in high-temperature applications?

Absolutely. Foamed polypropylene excels in high-temperature applications. Its structure maintains integrity and performance under extreme heat, ensuring your cables remain functional and reliable.

What industries benefit most from foamed polypropylene?

Industries such as telecommunications, automotive, and aerospace benefit significantly from foamed polypropylene. You will find it enhances signal integrity, reduces weight, and improves fuel efficiency, among other advantages.

How does foamed polypropylene contribute to energy efficiency?

Foamed polypropylene minimizes energy loss through its superior insulation properties. You experience lower energy consumption, which translates to cost savings and environmental benefits.

What are the transportation advantages of using foamed polypropylene?

The reduced weight of foamed polypropylene lowers transportation costs and minimizes the risk of damage during transit. You benefit from easier handling, improving safety and efficiency in logistics.

How do I ensure compatibility with existing systems when using foamed polypropylene?

To ensure compatibility, evaluate your current systems for potential conflicts. Consult with manufacturers or experts to confirm that foamed polypropylene aligns with your system’s specifications, optimizing performance and maintaining integrity.

What maintenance practices should I follow for foamed polypropylene insulation?

Regular monitoring and inspection are crucial. Develop a routine schedule to assess cable conditions, looking for signs of wear or damage. Utilize advanced inspection tools to detect issues early, ensuring continuous operation and extending insulation lifespan.

Post time: Dec-19-2024