Fluorescent whiteners-Polyester transform polyester fabrics by absorbing ultraviolet light and converting it into visible light. This process creates a brighter and more vibrant appearance. You can rely on these whiteners to counteract yellowing, which often affects polyester over time. Their innovative design ensures that textiles maintain a fresh, high-quality look.

What Are Fluorescent Whiteners-Polyester?

Definition and Purpose

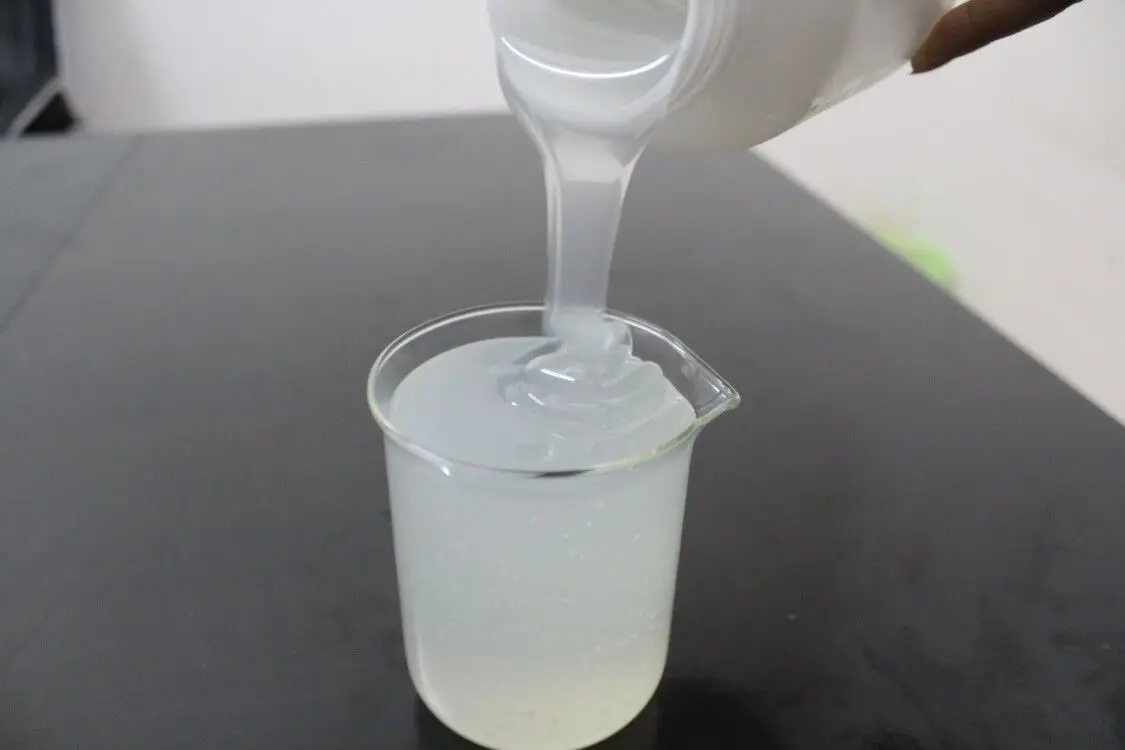

Fluorescent whiteners-Polyester are chemical agents that enhance the brightness and whiteness of polyester fabrics. These whiteners absorb ultraviolet (UV) light and convert it into visible light. This process creates a glowing effect that makes fabrics appear more vibrant. You can use these whiteners to counteract the yellowing caused by impurities or aging in polyester. Their primary purpose is to improve the visual appeal of textiles while maintaining their original quality.

Unique Application for Polyester

Polyester, a synthetic fiber, has unique properties that make it different from natural fabrics. Fluorescent whiteners-Polyester are specifically designed to work with polyester’s molecular structure. These whiteners bond effectively with the fibers, ensuring long-lasting brightness. Unlike other fabrics, polyester requires specialized treatment to achieve optimal whiteness. You will find that these whiteners provide a tailored solution for polyester, enhancing its appearance without compromising its durability.

Role in Modern Textile Manufacturing

In today’s textile industry, fluorescent whiteners-Polyester play a vital role. Manufacturers rely on these agents to meet consumer demands for high-quality fabrics. You will notice their widespread use in producing clothing, home textiles, and industrial materials. These whiteners help create products that stand out in the market. They also support efficient production processes by integrating seamlessly with other textile treatments. Their contribution ensures that polyester fabrics remain competitive and appealing in 2025.

How Do Fluorescent Whiteners Work?

UV Absorption and Visible Light Emission

Fluorescent whiteners absorb ultraviolet (UV) light, which is invisible to the human eye. They then convert this energy into visible light, creating a glowing effect. This process enhances the brightness of polyester fabrics, making them appear more vibrant. You can think of it as a way to amplify light, giving textiles a fresh and radiant look. The emitted light often falls in the blue spectrum, which helps counteract yellow tones in the fabric. This transformation ensures that polyester maintains a clean and appealing appearance.

Interaction with Polyester Fibers

Fluorescent whiteners interact directly with the molecular structure of polyester. These agents bond with the fibers, forming a stable connection. This bond ensures that the whitening effect lasts through multiple washes and extended use. Polyester’s synthetic nature makes it an ideal candidate for this treatment. You will notice that the whiteners integrate seamlessly with the fabric, enhancing its brightness without altering its texture or durability. This compatibility is key to achieving consistent results in textile manufacturing.

Factors Influencing Effectiveness

Several factors influence the performance of fluorescent whiteners. The concentration of the whitener plays a significant role. Using the right amount ensures optimal brightness without overloading the fabric. The application method also matters. Proper distribution across the fabric ensures uniform results. Additionally, environmental conditions like temperature and exposure to UV light can impact the effectiveness. You can achieve the best results by following recommended guidelines during the application process.

Benefits of Fluorescent Whiteners-Polyester

Enhanced Brightness and Whiteness

You will notice a remarkable difference in the brightness and whiteness of polyester fabrics treated with fluorescent whiteners-Polyester. These agents work by amplifying light, which gives the fabric a clean and radiant appearance. This enhancement is especially useful for counteracting yellowing caused by aging or impurities. The result is a fabric that looks fresh and vibrant, even after extended use. By using these whiteners, you can achieve a level of brightness that makes your textiles stand out in any setting.

Improved Aesthetic and Market Value

Fluorescent whiteners-Polyester significantly improve the aesthetic appeal of polyester fabrics. The enhanced brightness creates a polished and professional look, which is highly desirable in both fashion and home textiles. When your fabrics look better, their market value increases. Consumers are more likely to choose products that appear high-quality and visually appealing. By incorporating these whiteners into your textile production, you can meet consumer expectations and boost the competitiveness of your products in the market.

Durability and Long-Term Performance

You can rely on fluorescent whiteners-Polyester to deliver long-lasting results. These agents bond with polyester fibers, ensuring the whitening effect remains intact through multiple washes and regular use. This durability makes them an excellent choice for textiles that need to maintain their appearance over time. Whether you are producing clothing, upholstery, or industrial materials, these whiteners help ensure your fabrics retain their brightness and quality for years. This long-term performance adds value to your products and enhances customer satisfaction.

Relevance of Fluorescent Whiteners in 2025

Alignment with Consumer Trends

In 2025, consumer preferences continue to evolve, with a strong focus on quality and aesthetics. You will notice that buyers increasingly demand fabrics that look fresh, vibrant, and premium. Fluorescent whiteners-Polyester help you meet these expectations by enhancing the brightness and whiteness of polyester textiles. This improvement makes your products more appealing to consumers who value visually striking fabrics. Additionally, the rise of social media and online shopping has amplified the importance of appearance. Bright, clean fabrics stand out in photos and videos, making them more likely to attract attention and drive sales.

Contribution to Sustainability Goals

Sustainability remains a top priority for the textile industry in 2025. You can rely on fluorescent whiteners to support eco-friendly practices. These agents allow you to achieve superior brightness without resorting to harmful bleaching processes. Many modern whiteners, including those from innovative brands like Jindun, are designed with environmental safety in mind. By using these products, you contribute to reducing the environmental impact of textile production. This aligns your business with global sustainability goals and appeals to eco-conscious consumers.

Advancements in Textile Technology

The year 2025 has brought significant advancements in textile technology. You can now integrate fluorescent whiteners seamlessly into automated production lines. This innovation ensures consistent application and reduces waste. Modern whiteners also offer improved compatibility with other textile treatments, such as softeners and water repellents. These advancements make it easier for you to produce high-quality fabrics efficiently. By leveraging these technologies, you stay ahead in a competitive market while delivering products that meet the highest standards.

Fluorescent whiteners-Polyester offer you an essential tool for creating brighter, more vibrant textiles. Their ability to transform UV light into visible brightness ensures fabrics meet modern aesthetic standards.

Post time: Jan-09-2025