In the world of construction, you face numerous challenges that demand innovative solutions. AlKali -Resistant glass fibre emerges as a game-changer, directly addressing these issues. Its unique properties make it an ideal choice for modern construction projects. This material resists chemical degradation, ensuring durability and longevity. You benefit from its ability to withstand harsh environmental conditions, reducing maintenance needs. By choosing AlKali -Resistant glass fibre, you enhance the strength and reliability of your structures, paving the way for sustainable and efficient building practices.

Key Takeaways

- Alkali-Resistant glass fiber enhances the durability of construction materials, making them resistant to chemical degradation and environmental factors.

- Investing in Alkali-Resistant glass fiber reduces long-term maintenance costs, as structures require fewer repairs and have extended lifespans.

- This innovative material supports sustainable building practices by lowering the carbon footprint and minimizing waste during production.

- Projects using Alkali-Resistant glass fiber can achieve green building certifications, showcasing a commitment to environmental responsibility.

- Choosing Alkali-Resistant glass fiber can lead to significant cost savings over time, despite a higher initial investment.

- Real-world applications demonstrate the effectiveness of Alkali-Resistant glass fiber in challenging environments, such as coastal areas exposed to saltwater.

Enhancing Durability in Construction

Understanding Durability Challenges

Common issues with traditional materials

In construction, traditional materials often face significant durability challenges. You might notice that materials like wood, steel, and concrete can degrade over time. Wood can rot or warp, steel may rust, and concrete can crack. These issues arise from exposure to moisture, temperature changes, and other environmental factors. Such degradation not only affects the appearance of structures but also compromises their safety and longevity.

Impact of environmental factors on construction materials

Environmental factors play a crucial role in the durability of construction materials. You must consider elements like rain, wind, and temperature fluctuations. These factors can cause materials to expand, contract, or erode. For instance, moisture can seep into concrete, leading to cracks and weakening the structure. Similarly, extreme temperatures can cause materials to become brittle or lose their structural integrity. Understanding these challenges is essential for selecting materials that can withstand such conditions.

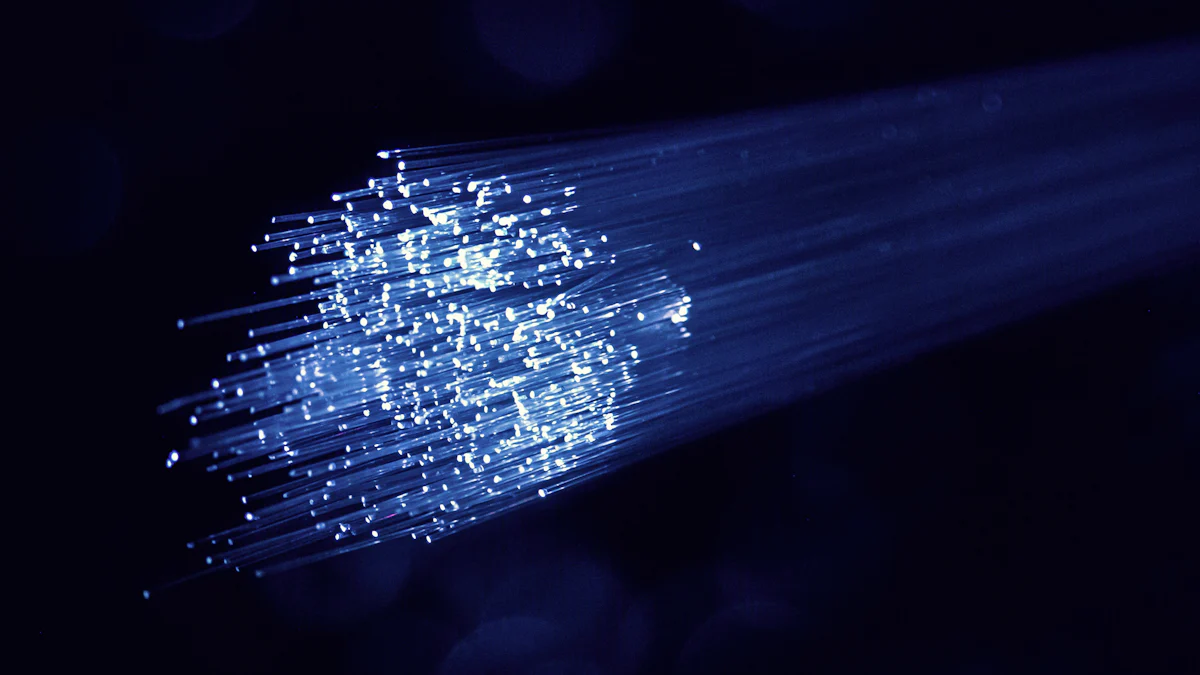

How Alkali-Resistant Glass Fiber Provides a Solution

Resistance to chemical degradation

Alkali-Resistant glass fiber offers a robust solution to the durability challenges faced by traditional materials. This innovative material resists chemical degradation, making it ideal for environments where exposure to harsh chemicals is common. You benefit from its ability to maintain structural integrity even in the presence of alkaline substances, which often cause damage to conventional materials. This resistance ensures that your structures remain strong and reliable over time.

Longevity and maintenance benefits

Using Alkali-Resistant glass fiber in construction projects provides significant longevity and maintenance benefits. You will find that structures built with this material require less frequent repairs and upkeep. Its durability reduces the need for costly maintenance, saving you time and resources. By choosing Alkali-Resistant glass fiber, you invest in a material that extends the lifespan of your structures, ensuring they remain safe and functional for years to come.

Real-World Examples

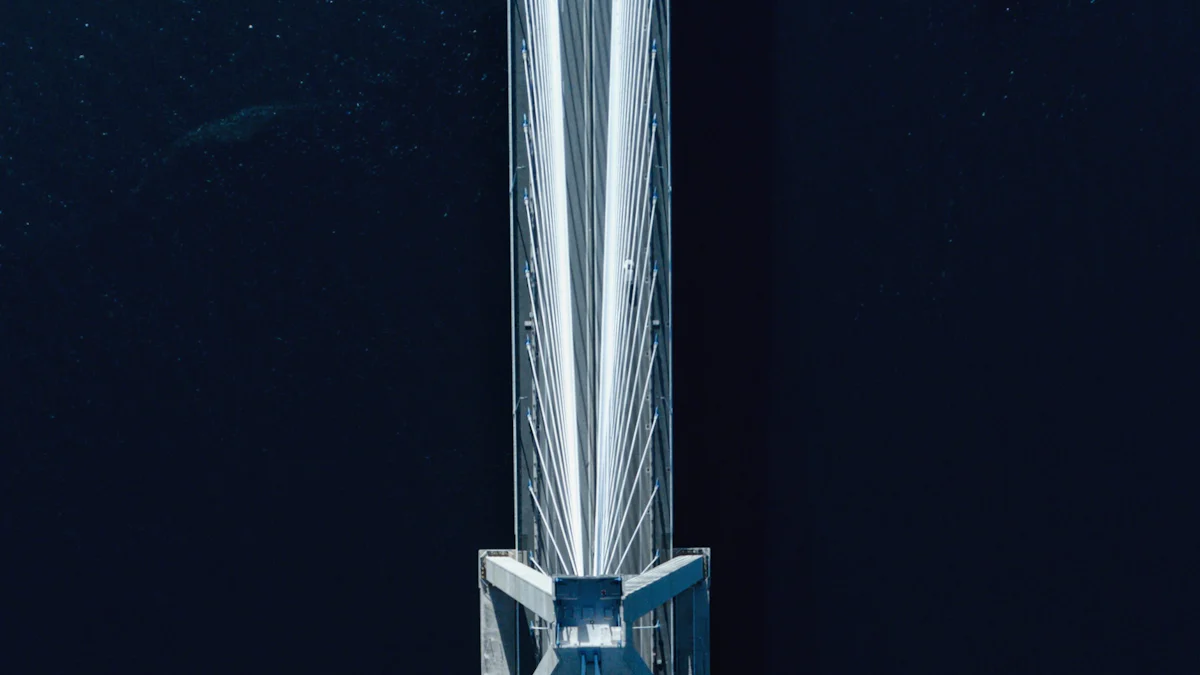

Case study of a successful project using alkali-resistant glass fiber

Consider a recent project where Alkali-Resistant glass fiber played a pivotal role. In a coastal city, a new bridge faced challenges due to saltwater exposure. Engineers chose Alkali-Resistant glass fiber to reinforce the concrete. The result? The bridge demonstrated exceptional durability, withstanding the corrosive effects of saltwater. This case highlights the effectiveness of Alkali-Resistant glass fiber in enhancing structural resilience.

Testimonials from industry professionals

Industry professionals consistently praise Alkali-Resistant glass fiber for its performance. One construction manager noted, “Using Alkali-Resistant glass fiber transformed our approach to building in challenging environments. We saw a marked improvement in the durability of our projects.” Such testimonials underscore the material’s value in modern construction, providing you with confidence in its application.

Cost-Effectiveness of Alkali-Resistant Glass Fiber

Cost Challenges in Construction

Initial investment vs. long-term savings

In construction, you often face the dilemma of balancing initial costs with long-term benefits. Traditional materials might seem cheaper upfront. However, they can lead to higher expenses over time due to frequent repairs and replacements. When you invest in Alkali-Resistant glass fiber, you make a strategic choice. This material may require a higher initial investment, but it offers substantial savings in the long run. Its durability reduces the need for constant maintenance, allowing you to allocate resources more efficiently.

Cost of repairs and maintenance with traditional materials

Traditional construction materials often incur significant repair and maintenance costs. You might find yourself dealing with issues like corrosion, cracking, or degradation. These problems not only demand financial resources but also disrupt project timelines. By choosing Alkali-Resistant glass fiber, you minimize these challenges. Its resistance to environmental factors ensures that your structures remain intact, reducing the frequency and cost of repairs.

Economic Benefits of Using Alkali-Resistant Glass Fiber

Reduction in repair costs

Using Alkali-Resistant glass fiber leads to a noticeable reduction in repair costs. You benefit from its ability to withstand harsh conditions without deteriorating. This resilience means fewer repairs and less downtime for your projects. As a result, you can focus on new developments rather than constantly addressing maintenance issues.

Increased lifespan of structures

Alkali-Resistant glass fiber significantly extends the lifespan of your structures. Its robust nature ensures that buildings and infrastructure remain functional for longer periods. You gain peace of mind knowing that your investments are protected. This longevity translates into cost savings, as you avoid the expenses associated with premature replacements.

Case Studies Demonstrating Cost Savings

Analysis of projects with significant cost reductions

Consider projects where Alkali-Resistant glass fiber has been implemented. In one instance, a commercial building project experienced a 30% reduction in maintenance costs over five years. The use of this material minimized structural issues, leading to fewer repairs. Such examples highlight the financial advantages of incorporating Alkali-Resistant glass fiber into your construction plans.

Financial testimonials from construction firms

Construction firms frequently report positive financial outcomes when using Alkali-Resistant glass fiber. One firm stated, “Switching to Alkali-Resistant glass fiber transformed our budget management. We saw a significant decrease in repair expenses, allowing us to invest in other areas.” These testimonials reinforce the economic benefits of this innovative material, providing you with confidence in its cost-effectiveness.

Environmental Impact and Sustainability

Environmental Challenges in Construction

Carbon footprint of traditional materials

Traditional construction materials often leave a significant carbon footprint. You might not realize it, but producing materials like steel and concrete releases large amounts of carbon dioxide into the atmosphere. This contributes to global warming and climate change. When you choose these materials, you inadvertently support processes that harm the environment. Understanding this impact is crucial for making informed decisions about the materials you use.

Waste and resource consumption

Construction projects generate a lot of waste. You may notice piles of unused materials and debris at construction sites. This waste not only takes up space but also strains landfills. Additionally, the production of traditional materials consumes vast amounts of natural resources. You might not see it directly, but this consumption depletes forests, water sources, and mineral reserves. Recognizing these challenges helps you appreciate the need for more sustainable practices.

Sustainable Benefits of Alkali-Resistant Glass Fiber

Lower environmental impact during production

Alkali-Resistant glass fiber offers a more sustainable alternative. Its production process emits fewer greenhouse gases compared to traditional materials. When you opt for this material, you contribute to reducing the overall carbon footprint of your projects. This choice supports a cleaner environment and aligns with global efforts to combat climate change.

Contribution to sustainable building practices

Using Alkali-Resistant glass fiber promotes sustainable building practices. You help create structures that last longer and require fewer resources over time. This material’s durability means less frequent replacements and repairs, which reduces waste. By incorporating it into your projects, you support a more sustainable construction industry that values long-term environmental health.

Examples of Sustainable Projects

Green building certifications achieved

Many projects using Alkali-Resistant glass fiber have earned green building certifications. These certifications recognize efforts to minimize environmental impact. When you use this material, you increase your chances of achieving such recognition. It demonstrates your commitment to sustainability and can enhance your project’s reputation.

Recognition in sustainable construction awards

Projects featuring Alkali-Resistant glass fiber often receive accolades in sustainable construction awards. These awards highlight innovative approaches to building that prioritize the environment. By choosing this material, you position your projects as leaders in sustainable construction. This recognition not only boosts your credibility but also inspires others to follow suit.

In summary, using alkali-resistant glass fiber in construction offers numerous benefits. You enhance the durability and longevity of your structures, reducing maintenance needs. This material also provides cost savings by minimizing repair expenses and extending the lifespan of buildings. Environmentally, it supports sustainable practices by lowering the carbon footprint and waste production. As an industry professional, you should consider adopting this innovative material for future projects. By doing so, you contribute to a more efficient, durable, and sustainable construction industry.

FAQ

What is alkali-resistant glass fiber?

Alkali-resistant glass fiber is a type of material designed to withstand chemical degradation, especially in environments with high alkaline content. You can use it to reinforce concrete and other construction materials, enhancing their durability and longevity.

How does alkali-resistant glass fiber improve construction durability?

This material resists chemical attacks and environmental factors that typically degrade traditional materials. By incorporating it into your projects, you ensure that structures remain strong and reliable over time, reducing the need for frequent repairs.

Is alkali-resistant glass fiber cost-effective?

Yes, it is. While the initial investment might be higher than traditional materials, you save money in the long run. Its durability reduces maintenance and repair costs, allowing you to allocate resources more efficiently.

Can alkali-resistant glass fiber contribute to sustainable building practices?

Absolutely. The production of alkali-resistant glass fiber emits fewer greenhouse gases compared to traditional materials. By using it, you support sustainable construction practices and help reduce the carbon footprint of your projects.

What types of projects benefit most from alkali-resistant glass fiber?

Projects exposed to harsh environmental conditions, such as coastal structures or industrial facilities, benefit significantly. You can also use it in any project where durability and longevity are priorities.

How does alkali-resistant glass fiber affect the lifespan of structures?

It significantly extends the lifespan of buildings and infrastructure. By resisting environmental and chemical degradation, it ensures that your structures remain functional and safe for longer periods.

Are there any certifications associated with using alkali-resistant glass fiber?

Many projects using this material have earned green building certifications. These certifications recognize efforts to minimize environmental impact, enhancing your project’s reputation for sustainability.

How does alkali-resistant glass fiber compare to traditional materials like steel?

Unlike steel, alkali-resistant glass fiber does not rust or corrode. It provides a 100% inorganic solution, making it a robust alternative for reinforcing non-load-bearing cement components.

What industries can benefit from alkali-resistant glass fiber?

Construction, infrastructure, and industrial sectors can all benefit. You can use it in residential buildings, commercial projects, and large-scale infrastructure developments to enhance durability and sustainability.

How do I incorporate alkali-resistant glass fiber into my construction projects?

You can integrate it into your existing formulations or use it as a reinforcement in concrete and other materials. Consult with industry professionals or suppliers to determine the best application methods for your specific needs.

Post time: Dec-19-2024